When it comes to protecting your basement from flooding, a sump pump plays a vital role. This guide will walk you through everything you need to know about sump pumps, including their types, choosing the right one, installation process, and essential maintenance tips to keep them running smoothly.

Contents

What is a sump pump

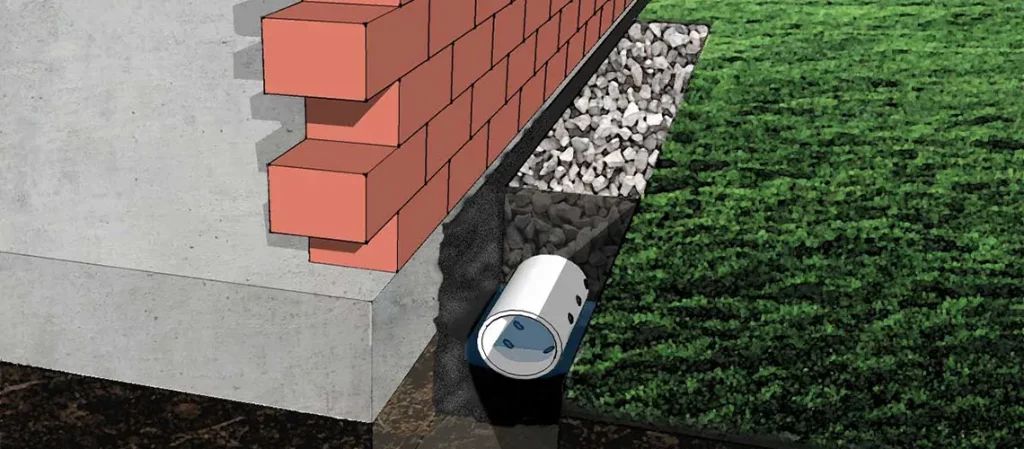

A sump pump is a device designed to remove excess water from the basement or crawl space of a building. It is typically installed in a sump pit or basin and activated by a float switch that detects rising water levels. Once triggered, the pump automatically starts, pumping the water away from the foundation to prevent flooding.

Types of sump pumps

There are several types of sump pumps available, each with its own advantages and suitable applications. Let’s explore the most common types.

Submersible pump

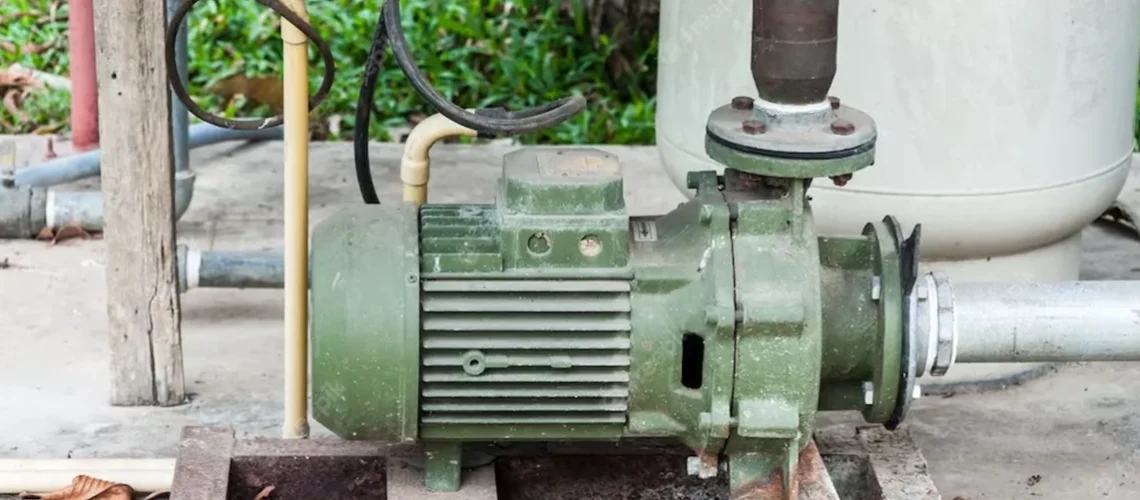

A submersible pump is a popular choice for sump pump installations, particularly in larger basements or areas prone to heavy flooding. This type of pump is designed to be fully submerged in the water-filled sump pit, which allows for efficient water removal. One of the key advantages of a submersible pump is its power and performance. These pumps are typically more powerful than other types, allowing them to handle larger volumes of water and pump it out quickly.

This is especially important in situations where the water level rises rapidly or during heavy rainstorms when there is a significant influx of water. The submersible pump consists of a motor, impeller, and a waterproof housing. The motor is sealed and protected, allowing it to operate underwater without the risk of damage. The impeller, driven by the motor, creates a centrifugal force that pushes the water out of the sump pit and through the discharge pipe. Installing a submersible pump involves placing it directly into the sump pit, ensuring that it is securely positioned and the float switch is properly adjusted.

The float switch plays a crucial role in activating the pump when the water level rises above a certain point. It signals the pump to start, pumping out the water until the level drops, and then automatically shuts off. One of the benefits of a submersible pump is its quieter operation compared to pedestal pumps, which have the motor located above the water level.

The submerged design helps dampen noise, making it a preferred choice for residential applications where noise reduction is desired. When it comes to maintenance, submersible pumps generally require less upkeep. Being submerged in the water helps keep the pump cool, which can contribute to its longevity. However, it is still important to periodically inspect and clean the pump, removing any debris or sediment that may have accumulated to ensure optimal performance.

Pedestal pump

In situations where space is limited or when a lower-cost option is desired, a pedestal pump is a suitable choice for sump pump installations. Unlike submersible pumps that are fully submerged in the sump pit, a pedestal pump has its motor positioned above the water level while the pump itself is located inside the pit. One of the primary advantages of a pedestal pump is its accessibility for maintenance and repairs. With the motor positioned above the water, it is easier to access and service compared to submersible pumps.

This accessibility makes it convenient to perform routine maintenance tasks such as cleaning the pump and inspecting the float switch. The pedestal pump consists of a motor, impeller, and a long shaft that extends into the sump pit. The motor, located on top of the pump, drives the impeller to create a centrifugal force that moves the water through the pump and out of the discharge pipe. When installing a pedestal pump, it is important to position the pump securely on a pedestal or platform to elevate it above the water level.

This ensures that the motor remains dry and protected. The float switch, which activates the pump when the water reaches a certain level, should be properly adjusted to ensure reliable operation. While pedestal pumps may not be as powerful as submersible pumps, they are still capable of effectively removing water from the sump pit. They are particularly well-suited for smaller basements or areas with limited space where a compact design is essential.

It is important to note that pedestal pumps tend to be louder during operation compared to submersible pumps. This is because the motor is located outside of the water and not insulated by it. However, advancements in motor design have led to quieter pedestal pumps being available on the market. When it comes to maintenance, pedestal pumps require periodic cleaning and inspection to ensure proper functionality. This includes removing any debris or sediment that may have accumulated in the sump pit or around the impeller. Regular maintenance helps extend the lifespan of the pump and ensures it operates efficiently.

Floor sucker

When it comes to addressing water accumulation on flat surfaces, such as concrete floors, a floor sucker pump, also known as a dewatering pump, is the ideal solution. These pumps are specifically designed to remove water efficiently from large open areas. Floor sucker pumps are commonly used in construction sites, basements, or areas where temporary water accumulation occurs. They are portable and versatile, allowing them to be easily moved around as needed.

It consists of a motor, impeller, and housing. The motor drives the impeller, creating a suction force that draws in the water and then pumps it out through the discharge hose. One of the key advantages of floor sucker pumps is their ability to handle water containing debris, solids, or small particles. The impeller is designed to pass solids without clogging, allowing the pump to efficiently remove water even in dirty or sediment-laden environments.

When using a floor sucker pump, it is important to position the pump at the lowest point of the water accumulation area to ensure effective drainage. The intake or suction port of the pump should be placed directly in contact with the water for optimal performance. These pumps are typically powered by electricity. It’s important to note that some floor sucker pumps may require a specific voltage or power supply, so be sure to check the manufacturer’s instructions and specifications.

Maintenance for floor sucker pumps is relatively simple. Regularly inspect the pump for any debris or clogs, and clean the intake and discharge ports as needed. Ensure the power cord and connections are in good condition, and replace any damaged parts promptly. Additionally, follow the manufacturer’s recommendations for lubrication and general upkeep.

Water-powered pumps

Water-powered pumps offer an alternative solution for sump pump installations, relying on the pressure from your home’s water supply to remove excess water from the sump pit. These pumps operate without the need for electricity, making them a valuable backup option in case of power outages or when electrical access is limited. The principle behind water-powered pumps is based on hydraulic energy. As water flows through the pump, it creates suction that draws in the water from the sump pit.

This water is then discharged through a separate hose, typically directed away from the foundation of the building. One of the main advantages of water-powered pumps is their reliability. As long as you have a functioning water supply, the pump will continue to operate. This makes them particularly useful in areas prone to severe storms or power disruptions, where the risk of flooding remains even during power outages. Water-powered pumps are also known for their efficiency.

They can remove large volumes of water quickly, providing effective flood protection for your basement or crawl space. However, it’s worth noting that water-powered pumps may not be as efficient as electric pumps in terms of the amount of water moved per gallon of water used. During installation, it’s important to connect the water-powered pump to a reliable water source, such as your municipal water supply or a well system.

It requires a dedicated water line to supply the pump with the necessary water pressure. It’s recommended to consult a professional plumber to ensure the installation is done correctly. One consideration when using water-powered pumps is the impact on your water bill. Since the pump relies on the water supply, there will be an increase in water consumption when the pump is in operation. However, the overall cost is generally lower compared to potential damage from flooding. Maintenance for water-powered pumps is relatively simple.

It mainly involves periodic inspections to ensure the pump is free from debris or sediment buildup. It’s also important to check for any leaks or signs of wear and tear, as well as verifying that the float switch is functioning correctly.

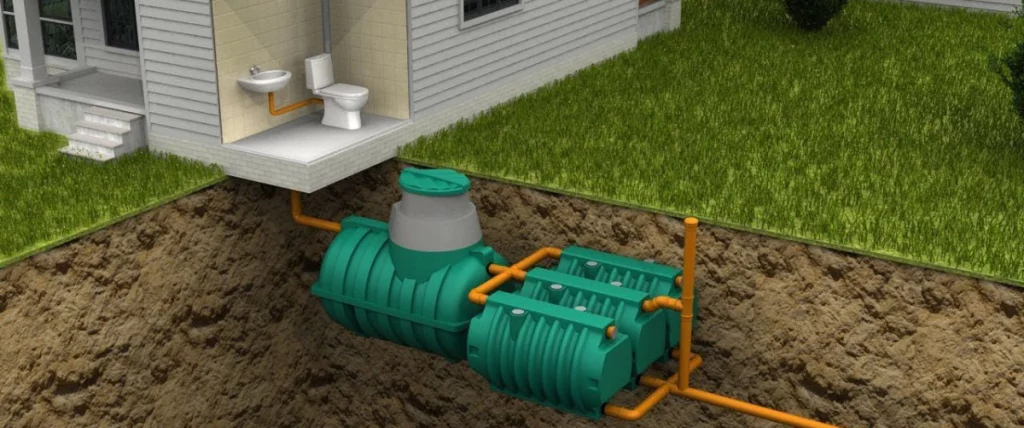

Ejector pumps

Ejector pumps, also known as sewage ejector pumps, are specifically designed to handle the drainage of wastewater or sewage from areas that are located below the main sewer line or septic tank level. These pumps are commonly used in basements or areas where gravity alone cannot effectively remove wastewater. The primary function of an ejector pump is to lift the wastewater or sewage to a higher elevation, allowing it to flow into the main sewer line or septic tank.

This is achieved through the use of a powerful impeller that can handle solids and debris commonly found in wastewater. Ejector pumps are typically installed in a sump pit, which collects the wastewater or sewage. The pump is positioned within the sump pit, and the discharge pipe is connected to the pump to carry the wastewater away. The pump is equipped with a float switch that activates the pump when the wastewater reaches a certain level, ensuring efficient and timely removal.

One of the key advantages of ejector pumps is their ability to handle large volumes of wastewater and solids. They are specifically designed for the demanding task of pumping sewage, which often contains debris, toilet paper, and other solid waste. The impeller in an ejector pump is robust and can effectively break down and move solid particles without clogging. Installation of an ejector pump requires careful consideration of the specific requirements and codes in your area.

It is recommended to consult a professional plumber or adhere to local building codes to ensure proper installation and compliance. Maintenance for ejector pumps involves regular inspections to ensure the pump and sump pit are free from debris or blockages. It’s important to clean the pump and check the impeller for any signs of wear or damage. Additionally, inspecting the float switch and ensuring its proper functioning is crucial for reliable operation.

It’s worth noting that ejector pumps are designed specifically for handling sewage or wastewater and should not be used for other types of water removal. They require a dedicated discharge line that is separate from other plumbing systems in the building.

Combination sump pump

A combination sump pump, also known as a dual sump pump, offers the benefits of both a primary and a backup pump in a single unit. This type of pump is designed to provide enhanced reliability and protection against basement flooding by offering redundancy in case of pump failure or power outages. The combination sump pump consists of two pumps: a primary pump and a backup pump. The primary pump is typically an electric submersible pump that operates under normal conditions, efficiently removing water from the sump pit.

The backup pump, on the other hand, is often a water-powered pump or a battery-powered pump that activates when the primary pump fails or when there is a power outage. The primary pump in a combination sump pump is typically the same as those used in standalone electric submersible pumps. It is powerful, efficient, and capable of handling the normal water removal needs of the sump pit. It is important to select a primary pump that matches the requirements of your specific application, considering factors such as the size of the sump pit and the potential volume of water accumulation.

The backup pump in a combination sump pump can vary in its operation. Some models use a water-powered backup pump that relies on the water supply to create suction and remove water from the sump pit. Others use a battery-powered backup pump that operates independently of the main power supply. Both options provide an extra layer of protection in case of primary pump failure or power outages. When installing a combination sump pump, it is essential to ensure proper placement and positioning of both the primary and backup pumps within the sump pit.

The float switches of both pumps should be adjusted to the appropriate levels to ensure reliable activation and operation. Maintenance for combination sump pumps involves regular inspections of both the primary and backup pumps. This includes checking for any debris or blockages, ensuring proper float switch operation, and testing the backup pump’s power source or battery to ensure readiness in case of an emergency.

How to choose a drainage pump

Choosing the right sump pump is crucial for effective water removal and flood prevention. Consider the following factors when selecting a sump pump:

- Determine the size of your basement or crawl space and the estimated volume of water that needs to be pumped out.

- Assess the water table and the frequency of flooding in your area.

- Consider the pump’s horsepower, pumping capacity, and head height to ensure it can handle your specific requirements.

- Look for additional features such as an alarm system, battery backup, and check valve for added reliability and convenience.

Remember to check local building codes and regulations and consult with a professional if needed. You can search for “sump pump installation near me” to find experienced professionals in your area.

How to clean a sump pump

Regular cleaning and maintenance are essential to keep your sump pump functioning properly. Here are the steps to clean your sump pump:

- Disconnect the power supply to the pump to ensure safety.

- Remove the pump from the sump pit by disconnecting the discharge pipe and lifting it out carefully.

- Inspect the pump for any debris or clogs. Use a hose to clean the pump and remove any dirt or sediment buildup.

- Check the float switch and ensure it moves freely. If necessary, clean or replace it.

- Inspect the check valve and clean or replace it if needed.

- Reassemble the pump, reconnect the discharge pipe, and place it back into the sump pit.

- Test the pump by pouring water into the pit and ensuring it activates and pumps the water out properly.

| Step | Instructions |

| Turn Off Power | Ensure safety by turning off the power to the sump pump at the breaker. |

| Remove the Pump | Carefully remove the pump from the pit. Disconnect it from any pipes if necessary. |

| Clean the Pump | Use a garden hose to wash off mud and debris. For tougher grime, a brush may be needed. |

| Inspect and Clean the Check Valve | Remove the check valve, inspect it for damage or blockages, and clean it with water. |

| Check the Discharge Line | Ensure the line is free of obstructions. Flush it with water if possible. |

| Reassemble and Test | Reinstall the pump and check valve. Restore power and pour water into the pit to test the pump. |

Regular cleaning and maintenance will help prevent clogs, prolong the lifespan of your sump pump, and ensure its optimal performance.

In conclusion, choosing a sump pump, installing it correctly, and maintaining it are essential steps in protecting your basement from flooding. By understanding the types of sump pumps available, considering your specific needs, and following proper cleaning and maintenance procedures, you can have peace of mind knowing that your sump pump is ready to safeguard your property.

FAQ about Drainage Pumps

Before buying a sump pump, it’s important to consider factors such as the size of your basement or crawl space, the average water accumulation, the power source availability, the type of pump (submersible or pedestal), and any specific features or requirements you may have.

The frequency of a sump pump’s operation depends on the amount of water entering the sump pit. It can vary based on factors like rainfall, groundwater levels, and the overall drainage conditions in your area. Some pumps may run a few times a day, while others may operate less frequently.

There are several signs that indicate your sewer may not be working properly. These include slow drainage in sinks, toilets, or showers, gurgling sounds coming from drains or toilets, sewage odors in the house or yard, frequent backups or clogs, and the presence of standing water or wet areas around the sewer lines. If you notice any of these signs, it’s advisable to contact a professional plumber to assess and address the issue.