Faucets are integral to our daily lives, yet they are often overlooked until a problem arises. From annoying drips to low water pressure, faucet issues can disrupt your daily routine and lead to higher water bills. This guide will help you understand common faucet problems and provide step-by-step solutions to fix them yourself.

Different faucets have unique mechanisms that affect how they operate and are repaired. Understanding the type of faucet you have is crucial for effective troubleshooting.

Contents

Compression Faucets

Compression faucets are the oldest type, using a washer that compresses against a valve seat. Common issues include leaking and dripping, typically caused by a worn-out washer or seat.

Compression faucets are one of the oldest and most common types of faucets found in homes. They operate using a simple mechanism where a handle is turned to raise or lower a stem, which in turn opens or closes a rubber washer against a valve seat to control the flow of water. Here’s a closer look at the characteristics, function, and common issues associated with compression faucets:

How Compression Faucets Work

A compression faucet consists of two crucial components: the valve seat and the washer. When the handle is turned, the stem (which is attached to the handle) either rises or lowers. As the stem moves, the washer at the bottom of the stem comes into contact with the valve seat. This washer seals the opening to stop the water flow when the handle is closed. Turning the handle in the opposite direction lifts the washer off the seat, allowing water to flow.

Common Issues and Solutions

- Leaks: The most common issue with compression faucets is leaking, which typically occurs when the washer or the valve seat becomes worn out. The constant friction during operation can cause the washer to lose its ability to form an effective seal, resulting in a drip or leak.

- Solution: Replacing the washer is often the first step in addressing a leak. If the leak persists, the problem might be with the valve seat. If the seat is worn or corroded, it may also need to be replaced or resurfaced.

- Stiff Handles: Over time, the packing nut and the stem assembly can become hard to turn due to sediment build-up or lack of lubrication.

- Solution: Loosening the packing nut slightly can free up the handle. If that does not work, disassembling the handle and applying a lubricant to the stem can restore movement. It’s also a good idea to clean any sediment buildup.

- Squeaking: A squeaking handle is usually a result of old packing material around the stem losing its lubrication.

- Solution: This can typically be resolved by replacing the packing material or applying a lubricant to the existing packing.

Maintenance Tips

Regular maintenance can greatly extend the life of a compression faucet and prevent many common issues:

- Check and replace washers regularly to avoid leaks. This is a simple and inexpensive fix that can prevent more significant problems.

- Clean aerators and exposed parts to prevent sediment buildup, which can affect water flow and pressure.

- Lubricate moving parts annually to ensure smooth operation and prevent wear.

Compression faucets, while traditional, are valued for their simplicity and the ease with which they can be repaired. With basic plumbing tools and a little know-how, most issues with these faucets can be quickly and inexpensively resolved, making them a durable choice for many households.

Ball-Type Faucets

These faucets use a ball bearing to control water flow and temperature. They are prone to leaks from wear and tear on the ball bearings or O-rings.

Ball-type faucets are a modern alternative to traditional compression faucets and are commonly found in kitchens and bathrooms. These faucets use a single handle to control both the temperature and the flow of water, making them very convenient to use. Here’s an overview of how ball-type faucets work, their common issues, and how to fix them:

How Ball-Type Faucets Work

A ball-type faucet has a single handle that moves over a rounded ball-shaped cap right above the base of the faucet spout. The ball has chambers or slots within it, and it controls the mixing of hot and cold water as well as the water flow. The handle’s movement causes the ball to align with the hot and cold water inlets in the faucet body, allowing water to flow through and mix to the desired temperature.

Common Issues and Solutions

- Leaks: Leaks are one of the most frequent problems with ball-type faucets. These can occur around the base of the faucet or at the handle.

- Solution: Most leaks in ball-type faucets can be resolved by replacing the O-rings, which are small rubber rings that prevent water from leaking around the moving parts. If the faucet continues to leak from the spout, replacing the ball assembly might be necessary.

- Inconsistent Water Flow or Temperature Control: If the faucet delivers water at inconsistent temperatures or flow rates, the issue might be with the ball assembly or the springs and washers that hold it in place.

- Solution: Disassembling the handle and inspecting the ball assembly for any signs of damage or wear is advised. Replacing the ball, springs, and washers can often resolve this issue.

- Difficulty in Handle Operation: If the faucet handle is hard to move, it could be due to mineral deposits or corrosion inside the faucet.

- Solution: Cleaning the faucet parts with a vinegar solution can help remove mineral deposits. Lubricating the moving parts, particularly the ball assembly and the handle mechanism, can also improve operation.

Maintenance Tips

Maintaining a ball-type faucet involves a few regular checks and routine tasks to ensure smooth operation and a long lifespan:

- Regular Cleaning: Regularly cleaning the faucet with mild soap and water can prevent the buildup of mineral deposits and grime.

- Periodic Inspections: Periodically inspect the faucet for signs of wear or damage, especially the O-rings and the ball assembly.

- Lubrication: Apply silicone-based lubricant to the ball assembly and other moving parts during routine maintenance to ensure smooth operation.

Ball-type faucets are appreciated for their durability and ease of use, but like any mechanical fixture, they require some maintenance to keep them functioning properly. Understanding the structure and common issues of your ball-type faucet can save you from costly plumbing repairs and provide a steady, reliable performance in your home.

Cartridge Faucets

Cartridge faucets are known for their durability. Problems usually stem from a worn cartridge that needs replacement.

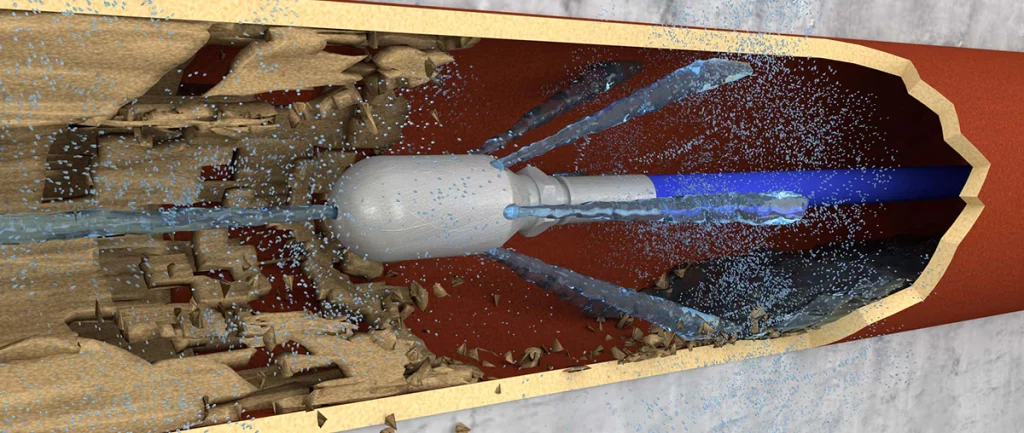

Cartridge faucets are widely used in modern plumbing installations due to their durability and ease of maintenance. These faucets operate with a movable cartridge within the faucet body, which regulates water flow and temperature with a simple up-and-down and side-to-side mechanism. Here’s an overview of how cartridge faucets work, their common problems, and solutions:

How Cartridge Faucets Work

A cartridge faucet typically has one or two handles. Single-handle cartridge faucets adjust water flow and temperature with one motion, moving up and down to control the flow and left and right to adjust the temperature. Dual-handle cartridge faucets have a separate handle for hot and cold water, similar to compression faucets but with smoother operation. The cartridge itself has holes that line up with the hot and cold water inlets in the faucet body, allowing for precise control over the mixture and flow of water.

Common Issues and Solutions

- Leaks: Like other types of faucets, cartridge faucets can develop leaks. These are often due to a worn or damaged cartridge.

- Solution: Replacing the cartridge is usually the best fix for leaks in these faucets. It’s a relatively straightforward process: remove the handle, unscrew the retaining nut (if present), and pull out the old cartridge. Insert a new cartridge in the same orientation as the old one, reassemble the faucet, and test for leaks.

- Stiff Handle: If the faucet handle is difficult to move, it could be caused by mineral buildup or an old cartridge that needs lubrication or replacement.

- Solution: First, try cleaning the cartridge and the faucet assembly with vinegar or a commercial calcium, lime, and rust remover. If the problem persists, replace the cartridge. Lubricating the new cartridge with plumber’s grease can also help ensure smooth operation.

- Inconsistent Water Temperature or Flow: Issues with water temperature or flow often point to a malfunctioning cartridge, especially if the faucet does not mix hot and cold water properly.

- Solution: This typically requires replacing the cartridge. Ensure that the replacement cartridge is the correct type for your faucet model to maintain proper function.

Maintenance Tips

To keep a cartridge faucet in optimal condition, consider these maintenance tips:

- Regular Cleaning: Keep your faucet clean from buildup and debris by regularly wiping it with a mild cleaner and soft cloth.

- Inspect and Replace Cartridges Periodically: Even though cartridge faucets are known for their longevity, the cartridges can wear out and should be replaced when you notice a drop in performance.

- Check for Worn O-Rings and Seals: When replacing the cartridge, it’s also a good time to replace any worn O-rings or seals to prevent future leaks.

Cartridge faucets offer a convenient and reliable option for modern plumbing systems. Their straightforward design makes them easier to maintain than other types of faucets, and with proper care, they can provide years of trouble-free use. Knowing how to address common issues with cartridge faucets can help you save on plumbing costs and extend the lifespan of your fixtures.

Ceramic-Disk Faucets

Featuring a modern design, these faucets use ceramic disks to control flow. They are highly durable but can face issues if grit or sediment disrupts the ceramic plates.

Ceramic-disk faucets are among the most durable and modern faucet types available today. They utilise two ceramic disks that slide against each other to control water flow and temperature, providing a seal that is almost maintenance-free. Here’s an overview of how ceramic-disk faucets work, their common issues, and solutions:

How Ceramic-Disk Faucets Work

Ceramic-disk faucets have a single lever over a wide cylindrical body. The core of this faucet is the pair of ceramic disks at the base of the mixing chamber. One disk is fixed, while the other moves horizontally. As the handle is adjusted, the moving disk slides over the stationary disk, aligning or misaligning holes in the disks to control water flow and temperature. This design allows for a very precise control of flow and temperature, with the added benefit that the ceramic surfaces are nearly impervious to the mineral deposits that plague other faucet types.

Common Issues and Solutions

- Leaks: Common in ball-type faucets, often around the base or handle.

Fix: Replace worn O-rings or, if leaking from the spout, replace the ball assembly. - Inconsistent Water Flow or Temperature: Caused by a faulty ball assembly or worn springs and washers.

Fix: Disassemble the handle, inspect, and replace damaged components. - Stiff Handle Movement: Due to mineral buildup or corrosion.

Fix: Clean with a vinegar solution and lubricate moving parts.

Maintenance Tips

- Regular Cleaning: Prevents mineral buildup—use mild soap and water.

- Routine Inspections: Check O-rings and ball assembly for wear.

- Lubrication: Apply silicone-based lubricant to moving parts.

Ball-type faucets are durable but need maintenance to avoid leaks and performance issues. Regular care ensures long-lasting reliability.

Common Faucet Problems

Here is a table outlining common faucet problems, their causes, and potential solutions. This table covers various types of faucets, providing a broad perspective on typical issues that might arise and how to address them efficiently.

| Problem | Possible Causes | Solutions |

| Leaking Faucet |

|

|

| Dripping from Spout |

|

|

| Low Water Pressure |

|

|

| Squeaky Handle | Lack of lubrication (All types) | Lubricate the handle mechanisms. |

| Stiff Handle |

|

|

| Rusty or Corroded Components | High mineral content in water (All types) | Use water softeners, clean and replace parts as necessary. |

| Irregular Water Flow | Misaligned or obstructed valve components (All types) | Adjust or clean valve components. |

| Noise When Turned On | Loose parts or high water pressure (All types) | Tighten any loose parts and adjust water pressure. |

This table provides a comprehensive guide to identifying and solving common faucet issues across different faucet types. Each problem is addressed with specific solutions tailored to the type of faucet, ensuring that you can maintain and repair your faucets effectively.

Let’s delve into some typical problems and their DIY solutions.

Leaky Faucet

A leaky faucet is often due to a worn washer or seal. To fix, turn off the water supply, disassemble the faucet, and replace the faulty part.

Low Water Pressure

This can be caused by clogged aerators or pipes. Clean the aerator first; if the issue persists, inspect the pipes for possible obstructions.

Squeaky Handles

This annoyance is usually resolved by applying lubricant to the faucet’s handle mechanism.

Rust and Mineral Deposits

Regular cleaning with vinegar can prevent buildup. For severe cases, specialised cleaning products may be needed.

Advanced Troubleshooting Techniques

Some faucet issues require more than basic fixes, such as replacing worn-out parts like the valve seat or faucet stem. Here’s what you can do:

- Replace worn components – Identify faulty parts, purchase replacements, and follow installation guides.

- Adjust faucet settings – Some models allow flow and temperature adjustments; check the user manual for details.

When to Call a Professional

If you’ve tried multiple fixes with no success, it might be time to call a professional plumber. Complex issues like deep-seated leaks or major part replacements are best handled by experts.

Maintaining Your Faucet

Regular maintenance can prevent many problems. Periodically check for leaks, clean aerators, and replace worn parts before they fail.

With the right knowledge and tools, most common faucet issues can be resolved without the need for a professional. By following this guide, you can save time and money while keeping your faucets in optimal condition.

FAQs

Regularly replace worn parts and keep the faucet clean to prevent sediment build-up.

Clean it every three to six months, depending on water quality and usage.

Yes, but due to the precision required, make sure to follow a detailed guide.

This could be due to high water pressure or loose parts. Adjusting the water pressure or tightening components may help.

If repairs become too frequent or costly, replacing it with a modern, more efficient model might be more economical.